Demystifying hydrogen and its application to urban mobility

In recent years, the quest for sustainable and efficient urban mobility solutions has directed attention towards hydrogen as a promising alternative to fossil fuels. Characterised by its clean combustion, which only emits water vapour, hydrogen has the potential to revolutionise the urban mobility sector. Integrating ESG goals within the urban mobility sector, particularly through the adoption of hydrogen technologies, presents a strategic avenue to address some of the most pressing challenges of our times: climate change.

Environmentally, the shift towards hydrogen-fuelled vehicles drastically reduces greenhouse gas emissions and air pollutants, aligning with efforts to improve air quality in urban centres. Socially, this transition supports public health by minimizing pollution-related health issues, enhancing the quality of life for urban residents. However, is all hydrogen the same? Although the vehicles’ exhaust pipes only emit water vapour, is the hydrogen production chain 100% emissions-free?

This article is the first one of a trilogy envisioned by VTM about the potential application of hydrogen in the urban mobility realm. It aims to briefly introduce the hydrogen production chain and the different forms of hydrogen production.

Hydrogen production methods

The bad news is that not every source of hydrogen can be considered clean. Today, unfortunately, the global production of hydrogen is almost exclusively derived from fossil fuels and is by and large utilised in industries such as oil refining, fertilizer production, and downstream chemical processes. Current production of hydrogen emits the equivalent of 1,100-1,300 megatons of CO2 (Mt CO2) globally [1]. Thus, at present, hydrogen production is a major net contributor to climate change, rather than a catalyst for decarbonization. Therefore, currently, the process of producing hydrogen significantly adds to climate change instead of serving as a pathway to reduce carbon emissions.

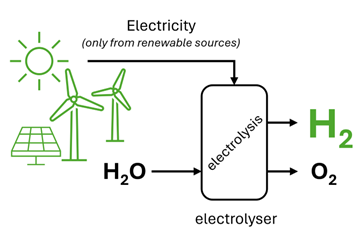

Hydrogen is an energy carrier that can be used as a substitute for coal, oil and gas in a large variety of applications. But for its use to have net environmental benefits, it must be produced from clean sources, rather than from fossil fuel processes – the usual method at present. Typically, hydrogen is generated either by transforming fossil fuels (a method called SMR that involves reacting natural gas with steam) or by splitting water into hydrogen and oxygen using a device called electrolyser that operates on electricity.

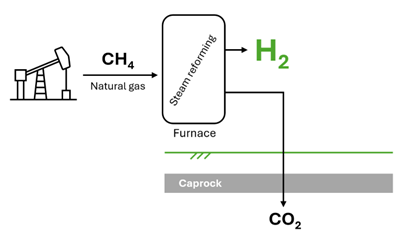

If the carbon emissions from the fossil fuel transformation are captured and secured using carbon capture and storage (CCS) techniques, the produced hydrogen is referred to as blue hydrogen. Conversely, when these emissions are not captured and are instead emitted into the air, the hydrogen produced is known as grey hydrogen. But these are not the only ways of producing hydrogen, as we can see in the following paragraphs.

To this day, hydrogen can be categorised into different types based on production methods and applications [2]:

Brown hydrogen is produced from coal using gasification or other processes. It is considered the most carbon-intensive method of hydrogen production as it involves extracting hydrogen from coal, which is a high-carbon fossil fuel. Brown hydrogen production generates substantial CO2 emissions and is not considered a clean or sustainable option.

Grey hydrogen refers to hydrogen produced from fossil fuels, such as natural gas or coal, through a process called steam methane reforming (SMR). The SMR technique employs steam and a catalyst to produce hydrogen by breaking down a light hydrocarbon like methane or propane. Raw natural gas contains around 90 per cent methane, five per cent propane, and five per cent other gases. Essentially, this method extracts hydrogen from the hydrocarbon and the water, converting all resulting carbon and oxygen into CO2. It is the most common method of hydrogen production today. However, grey hydrogen production generates carbon dioxide (CO2) emissions, contributing to climate change.

Blue hydrogen is produced from fossil fuels, similar to grey hydrogen, but with an additional step called carbon capture and storage (CCS) or carbon capture and utilisation (CCU). The CCS involves capturing the CO2 emitted during hydrogen production, transporting and storing it underground, and preventing it from entering the atmosphere. In addition to mitigating emissions from hydrogen production, CCS can be applied in different sectors, including cement, steel, fertilisers, power generation, and natural gas processing [3]. CCU refers to a range of applications through which CO2 is captured and used either directly (i.e. not chemically altered) or indirectly (i.e. transformed) into various products.

Figure 1: Blue hydrogen production process with CCS. Source VTM

Green hydrogen is produced using renewable energy sources, such as solar or wind power, through a process called electrolysis. Electrolysis involves splitting water (H2O) into hydrogen (H2) and oxygen (O2) using an electric current. Since it relies on renewable energy, green hydrogen production has no direct carbon emissions and is considered a clean and sustainable option.

Figure 2: Green hydrogen production process. Source VTM

Turquoise hydrogen, also known as low-carbon or decarbonised hydrogen, is produced using natural gas but with carbon emissions offset by capturing and storing the CO2, like blue hydrogen. The difference is that turquoise hydrogen production typically utilises a different type of methane reforming process called methane pyrolysis, which can help in reducing the carbon intensity of hydrogen production.

Pink hydrogen is the hydrogen produced from nuclear energy sources, specifically through high-temperature electrolysis (HTE). This method utilises heat generated by nuclear reactors to drive the electrolysis process, enabling the production of hydrogen without direct carbon emissions – although the drawbacks of nuclear power are known.

In 2022, almost all hydrogen consumption came from refining and industry [4]. However, according to the IEA [5], to reach net-zero by 2050, 40% of global hydrogen demand by 2030 should come from alternative sectors, such as transport, power generation, buildings and other industrial applications. IEA also estimates that emissions associated with current hydrogen production are equivalent to those of the UK and Indonesia combined, and less than 1% of this production can be considered clean.

According to the Global Hydrogen Review 2023 [6], hydrogen use is increasing, but demand remains so far concentrated in traditional uses in refining and the chemical industry and mostly met by hydrogen produced from unabated fossil fuels. To meet climate ambitions, there is an urgent need to switch hydrogen use in existing applications to low-emission hydrogen and to expand use to new applications in heavy industry and transport. Therefore, the challenges in the transport sector are twofold: incentivizing the transition from fossil fuels to hydrogen from the demand side perspective and guaranteeing greener ways of producing hydrogen from the supply side.

In sum, to make an environmentally safe use of hydrogen and avoid greenwashing in the urban mobility sector, it is paramount to consider the source of the hydrogen to power the engines of cars, buses, and other means of transport.

In the following article, we will dive into the opportunities and challenges of hydrogen fuel cell vehicles. Stay tuned!

References:

[1] IEA, IRENA and UN Climate Change High-Level Champions, 2023

[2] Hassan, Q.; Azzawi, I.D.J.; Sameen, A.Z.; Salman, H.M. Hydrogen Fuel Cell Vehicles: Opportunities and Challenges. Sustainability 2023, 15

[3] Global CCS Institute

[4] The Economist Intelligence Unit (2023)

[5] International Energy Agency

[6] IEA – Global Hydrogen Review 2023

Latest news

All news

Collaborative mobility planning takes a major step forward in Alto Minho

This week, Ponte de Lima hosted an important milestone for sustainable mobility in the Alto Minho region, with the working sessions of the 2nd-generation Sustainable Urban Mobility Plan of Alto Minho (SUMP Alto Minho), promoted by CIM Alto Minho. At VTM, we are proud to support CIM Alto Minho in the development of a new-generation […]

VTM welcomes Oriol Riba and Alessandra Bernardi

VTM is pleased to announce the addition of two highly experienced professionals, Oriol Riba and Alessandra Bernardi, further strengthening our capabilities across infrastructure advisory and transport modelling. Oriol Riba joins VTM as a Senior Associate Director with more than fourteen years of experience in the infrastructure sector, with a strong focus on transport and additional exposure to energy […]